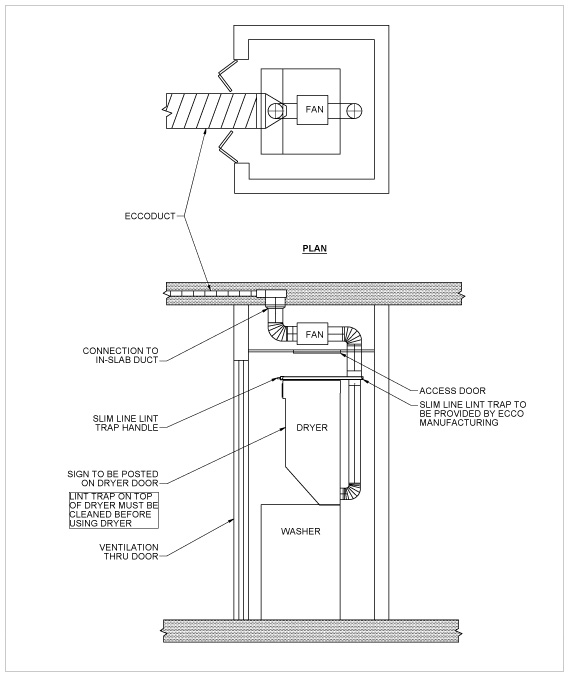

Dryer Vent Booster Fan

The idea behind a booster fan is to keep the water vapour/ steam suspended in the air until it reaches the outside of a building. This is done by increasing the volume of air passing through the duct each time the dryer is in use. The in-line fan must run when the dryer is running to be effective.

There are many styles of booster fans on the market today. We have found the Reversomatic TLD 200 or equivalent is the best for this application, installed with a amp sensor with 15 minute delay for activation. This fan is an in-line style fan, which means it has an inlet on one side and directly across has an outlet with no change in direction. A typical residential dryer should be vented no farther than 15'. To compound this each time you introduce a 90-degree bend this recommended vent length is cut in half. Most in slab dryer vents are 20' – 40' in length with numerous bends.

In-Slab Dryer Vent Problems:

- Sheet metal lined concrete ducts (usually 2"x12") are naturally cold.

- Hot, moist, lint filled air pass through these ducts the air rapidly cools to dew point and condensation and lint fibres fall out of the air.

- Condensation pools or drips from either end of duct.

- If the lint in the duct gets wet then dries it turns into a substance similar to papier-mâché.

- Ducts can be partially obstructed with concrete that has dripped through the seams of the sheet metal during construction.

- Some laundry rooms have been constructed with a false ceiling making it difficult to access the in slab duct/ 4 inch round duct joint. This joint is critical to get clean. what happens here is the air from the dryer is forced to make a rapid change in direction. so with that rapid change in direction air velocity is decreased causing lint and moisture to stick to all surfaces at this point